Related Topics:

Hydraulic Clutch System Overview

Clutch Master Cylinder Replacement

Bleeding the Clutch Hydraulic System

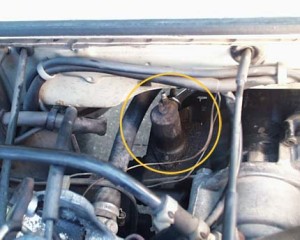

- Back in the left-forward corner of the engine compartment, just ahead of the edge of the deck-lid opening, you will find the clutch slave cylinder mounted to the clutch housing. Start by using some WD-40 and a shop rag to clean loose crud from the area, especially around the union nut on the steel high-pressure line entering the front of the slave cylinder. The introduction of dirt or other crud into your hydraulic system here or anywhere else will soon mean trouble. When clean, loosen but do not completely remove the union nut.

- Loosen the two retaining bolts attaching the slave cylinder to its mounting bracket. If yours are rusted and seized, and the penetrating oil hasn’t worked, you may need to use the propane torch to carefully apply some heat to them. NOTE: be very careful to not damage nearby wires or coolant hoses.

Use an open-end wrench to hold the bolt heads from beneath the bracket, while using a socket and ratchet to loosen the nuts from above. Alternatively, you may find you have better access while lying beneath the van.

Completely detach the high-pressure line from the slave cylinder, and withdraw the entire slave cylinder from its bracket. - If your old mounting bolts are rusty and corroded, replace them with new M8x25 bolts and nuts. Before dropping the new slave cylinder into place, you’ll want to be sure the rearmost (closest to you) mounting bolt is safely installed in its hole, as it will be impossible to get it in once the slave cylinder is in place. If necessary, prevent the bolt from falling out by temporarily threading its nut onto it.

- Put a dab of general-purpose grease into the small cup at the end of the slave cylinder actuator, to lubricate the ball on the clutch-engagement lever to which it will connect. Set the slave cylinder into place, making sure the cup engages the ball (it doesn’t need to ‘snap’ into place, but simply engage), and slip the slave cylinder over its mounting bolts (having previously removed the temporary nut from the rearmost mounting bolt). Loosely thread the nuts onto the mounting bolts but do not tighten yet.

- Start threading the pressure fitting into the slave cylinder by hand, then finish by wrench-tightening to 12 ft./lbs.. Tighten the mounting nuts to to 18 ft./lbs..

Once everything is satisfactorily reconnected, proceed to Bleeding the Vanagon Clutch Hydraulic System.