Here’s how to fix your van’s rear hatch if it won’t stay up or is difficult to open

If you (or more correctly, your van) has been suffering from a loose posterior opening (ahem), you probably need a new pair of hatch strut lift shocks.

In a pinch while traveling or camping, you can fashion a short length of one-inch-diameter firewood or similar to serve as a prop between the hatch door frame and the end of the shock portion of the strut.

But the correct fix, easy and affordable, is to replace the two hatch struts. We’ll start by propping up the open hatch, removing the old struts, and installing the new.

Parts & Materials

- Two hatch struts

- Steel wool

- WD-40 or all-purpose cleaner

- All-purpose auto grease

Optional Parts:

- E-clips, .25″ (6 mm) diameter, (qty. 2)

Tools

- Flat Screwdrivers; medium, small, and very small

- Pliers

Step 1: Removal

Open the hatch and if necessary prop it up with a 2×4 about 6-7 feet long, a broom handle wedged against the bumper, or an indulgent spouse. Before beginning to remove the old struts, double check the correct length of your new struts by holding them up alongside the old ones. The new struts may be up to 1/2″ longer, as the old ones are likely compressed and worn.

Open the hatch and if necessary prop it up with a 2×4 about 6-7 feet long, a broom handle wedged against the bumper, or an indulgent spouse. Before beginning to remove the old struts, double check the correct length of your new struts by holding them up alongside the old ones. The new struts may be up to 1/2″ longer, as the old ones are likely compressed and worn.

If your hatch is secure, you can remove and replace both struts together, or replace first one then the other.

Use an old screwdriver to loosen the safety clip on the top end of the strut attached to the raised hatch; you shouldn’t have to entirely remove the clip, but only loosen it. Once loosened, pull that end of the strut outward to pop it off of the ball stud. Let the strut dangle.

The other end of the strut has a simple flat rod end, attached to a pivot post on the door frame. The rod end is held onto the post by a small E-clip retaining ring and a couple of washers. Carefully pry this E-ring off the post using a very small screwdriver.

The other end of the strut has a simple flat rod end, attached to a pivot post on the door frame. The rod end is held onto the post by a small E-clip retaining ring and a couple of washers. Carefully pry this E-ring off the post using a very small screwdriver.

If you’re smart, you’ll first cover the E-clip with your hand or a shop rag to catch it when it pops off. If, instead, you’re like me, you’ll spend twenty minutes on your hands and knees searching the barn floor for the errant E-clip before finally driving to the hardware store for a new one. Ask the nice man there for a 1/4″ or 6 mm E-clip …

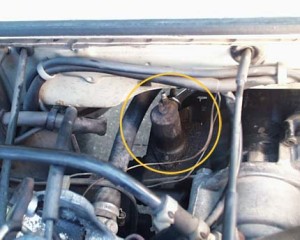

Remove and save both the rubber and steel washers, then remove the old strut. Both the ball stud and the pivot post will likely be dirty and rusted, so clean them up with WD-40 and a bit of fine steel wool. Apply a bit of grease to both.

Remove and save both the rubber and steel washers, then remove the old strut. Both the ball stud and the pivot post will likely be dirty and rusted, so clean them up with WD-40 and a bit of fine steel wool. Apply a bit of grease to both.

Step 2: Installation

Installation is the reverse of removal. You’ll have an easier time installing the new strut if you first attach the end on the door frame pivot post; slip it over the post, add the rubber and the steel washers, then carefully press the E-ring onto the post using pliers.

At the hatch end of the new strut, check that the ball socket is aligned with the ball stud. If not, carefully twist the black body of the strut clockwise (as if tightening a nut onto a bolt) until the socket aligns with the ball. They usually snap into place with only a firm push; but you may need to loosen the safety clip to allow it to connect.

At the hatch end of the new strut, check that the ball socket is aligned with the ball stud. If not, carefully twist the black body of the strut clockwise (as if tightening a nut onto a bolt) until the socket aligns with the ball. They usually snap into place with only a firm push; but you may need to loosen the safety clip to allow it to connect.

If the strut seems too long to fit, you may have to lift the supported hatch a bit higher, or forcefully compress the strut until it can be snapped into place.

Remove the temporary hatch support (or spouse) and carefully lower the hatch to close it. The first few times with new struts can be difficult until they wear in somewhat, but they should improve over time.

“The Haynes”

“The Haynes”